PCD AND PCBN TOOLS

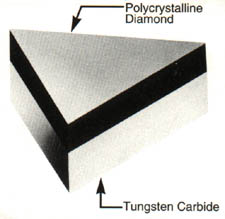

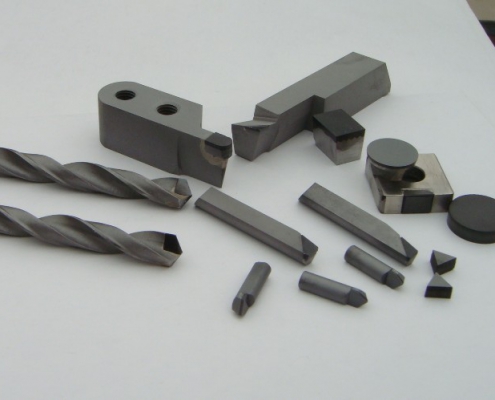

PCD Cutting tools can be easily used to machine non-ferrous and non-metalic components. Diamond, in its purest form, is essentially carbon. Carbon is known to have an affinity towards iron at higher temperatures. These temperature are quickly reached while machining at certain speeds. for this reason, diamond cannot be conveniently used for ferrous applications.

PCD Tools are most frequently applied in the automobile industry – comprising both heavy and light motor vehicles. Some of the materials that have been cost effectively machined with PCD Tools include; Hypo and hypereutectic aluminium alloys, Copper, bronze, babbit and abrasive plastic composites.

Although machining ferrous material is not recommended for PCD tools, they can be successfully used for certain cast iron applications where high speed is not attainable and where polycrystalline Cubic Boron Nitride (PCBN), Which is conventionally recommended for cast iron machining, connot be used. in such applications it is seen that PCD wears more slowly at lower speeds. when a critical speed is reached, it starts wearing faster because at this speed, the heat generated while machining is sufficient to cause the chemical reaction between iron and carbon. However, at low speeds, PCD tools have proved their worth on cast iron material by achieving much better results than conventional tools, maintaining high consistency of the work piece for a very long time.

The most significant application of PCD Cutting Tools, in this new generation of aluminium engine manufacturing is to machine dissimilar materials such as aluminium engines with grey cast iron cylinder liners – either cast or pressed along with the aluminium- which have to be finished machined, along with the aluminium blocks.