RESIN BONDED DIAMOND / CBN TOOLS AND WHEELS

This is a Diamond / CBN Wheel For your wheel to work efficiently

– Keep speed to within 4500-6000 S.F.P.M.

– True the Wheel to spindle before starting operation.

– Restrict depth of cut to 0.001” per pass.

– Use coolant wherever possible but use of coolant is a must for metal Bonded Wheels.

– Avoid Steel and Bronze materials as much as possible, when you are using a Diamond Wheel.

– For Flared Cup wheels having Diamond Cross-section in ‘V’ position, provide continuous relief to Diamond from Aluminum from the inside diameter.

– Avoid loading of wheel by exposure of clear cutting surface thru clearing by green silicon carbide stick during use whenever required for Resin and Metal Bonded Wheels and by a brush under water for Electro-plated wheels.

– Use wheel guard during grinding operation.

|

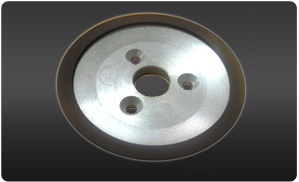

11V9 12A2

|

Milling Cutters, Reamers, Planning Tools, & Wood Saws Grinding

|

|

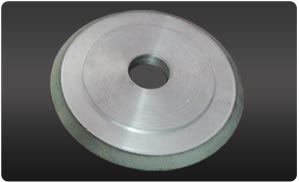

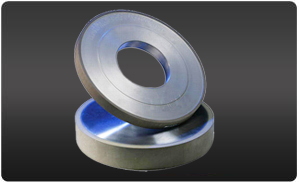

1A1 & 14A1

|

Surface or Cylindrical Grinding

|

|

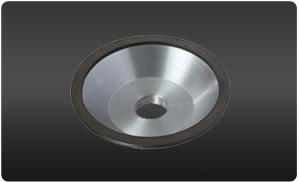

1F1 & 1EE1

|

Profiles Grinding

|

|

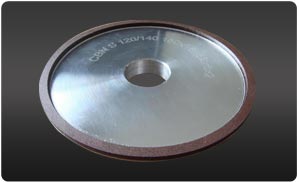

6A2

|

Tool Grinding

|

|

DWADWE1A8

|

Internal Grinding

|