DIAMOND AND CBN TOOLS

FIELDS OF APPLICATION

( Cutting / Grinding / Grooving / Polishing / Lapping / Ultra High Speed Grinding )

METAL WORKING :

General Production components, mechanical seals, Bearing seats & pivots, ceramic components, fuel injection valves, Hydraulic & pneumatic components, pump glands, etc.

TOOL ROOMS :

Press tools, tablet punches, test blocks, gauges, plastic moulds, slide surface, etc.

WIRE DRAWING :

Tungsten carbide dies, rolls, guides etc.

ELECTRONICS:

Semi-conductor wafers, laser rods, tape heads, Computer memory discs, radar tracking discs, etc.

OPTICS:

Contact lens moulds, stainless steel mirrors, Perspex prisms, etc.

LABORATORY:

Metallurgical, Geological, and Refractory specimens, Crystallography, Fiber optics etc.

PETROCHEMICALS :

Pump faces, valves seats, spinerettes , wear blocks etc.

AERONAUTICS :

Seal Plates of jet engines, hydraulic valves , spacer , etc.

SHIP BUILDING :

Diesel injector valves , pumps glands & seal factors, aluminium mirrors, etc.

DIAMOND NEEDLE FILES:

Diamond Files are offered in the form of Needle Files, Riffler Files, Diprofil Files in the normal sizes . Machine files also can be supplied against customer’s specifications.

GRIT SIZES:

Coarse : 80/100 – Medium : 140/170 – Fine: 200/230

FILE DIMENSION::

Thin Flat files of 1mm and 1.5mm Thickness can also be supplied as per customer’s requirements

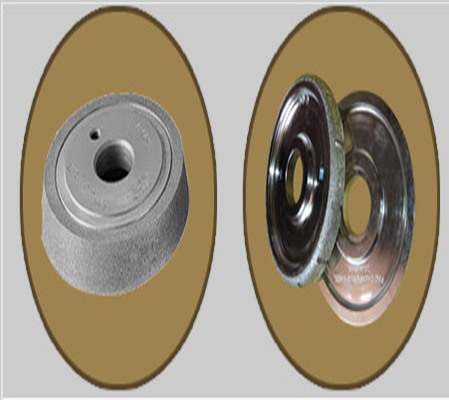

DIAMOND/CBN MOUNTED POINTS:

Electroplated Diamond / CBN Mounted points are used in Bore polishing of collect holding systems. CBN Mounted points are recommended for grinding materials of more than 45 HRC. Different Coating lengths will be provided as per customer’s requirement.

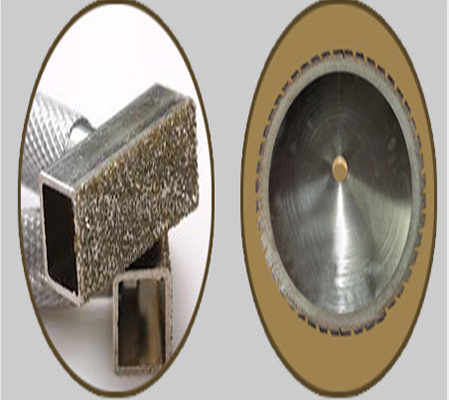

DIAMOND SLITTING SAWS:

Electroplated Diamond saws are advised for using in the manufacture of brake linings, Asbestos, Fibre and Reinforced plastic, Hard Plastics, Carbon industries etc. Metal Bond saws are suitable for sawing and slitting Tungsten carbide. Ceramics, Quartz, Glass etc. Slitting saws from 30mm dia to 650 mm dia can be supplied.

DIAMOND DRESSERS:

Diamond Dressers are made of Diamonds that have supreme hardness and high wear resistance. Available types are Single Point , Multi Point , Impregnated, Blade Type, Chisel Point, Cone Type and Indexable Crown, Cluster Diamond Dressers with shanks / holders as per customer’s specifications.

Manufacturers of single Point & Multi Point Dressers, Indenters, Diamond Powder & Paste and Diamond Grit impregnated Dressers

Single Point Diamond Dressers

In the last few decades, single point diamond dressers have, undoubtedly, emerged as the most widely used diamond dressing tools. The prime reason for the popularity of these tools is the versatility offered by them, as they can be used for truing as well as dressing of grinding wheels.

Manufactured using high quality raw diamond that is selected with utmost precaution, Win Win single point diamond dresser is formed by either mounting a natural diamond or a bruted diamond at the top of the tool by using a special adhesive. The diamond used in a single point diamond dresser is selected on the basis of the following parameters:

- Dimension of the grinding wheel

- Grit size

- Abrasive type

This tool is available in various sizes with the size and quality of the mounted diamond depending upon its usage. The range of single pint diamond dressers offered by us is available in sizes ranging from 0.50 Carat to 5.00 Carat. Depending upon the varying sizes of these single point diamond dressers, they can be used for soft wheels, medium hardness wheels and very hard type of wheels.

Guidelines While Using WIN WIN Single Point Diamond Dresser

To use the tool to its optimum level, it would be wise to keep the following guidelines in mind:

- Win Win diamond dresser should be mounted firmly into the holder and, the distance between the diamond and the clamp should be reduced to the least, so as to avoid the diamond from getting ruptured due to vibration.

-

Ensure that the diamond tool is never directed at an angle which is opposite to the direction of the rotation of the grinding wheel. To maintain a sharper point, it is essential to check that a drag angle of approximately 10 degrees to the horizontal wheel radius, pointing in the direction of grinding wheel rotation is maintained.

-

It is important not to insert Win Win dressers into the grinding wheel at more than 0.001” (0.025mm) per pass. Cuts deeper than this may cause overheating and, thereby, result in excessive wearing of the diamond.

- A fast traverse dressing rate will produce an open wheel, enabling removal of large stock. On the other hand, a slow traverse dressing rate will impart a finish on wheel which is appropriate for producing a good finish on the work piece.

- In order to maintain a conical point, Win Win dresser should be rotated in the holder at an angle varying from 20 to 40 degrees.

- To avoid cracking of the diamond, use ample amount of coolant wherever possible. Always make sure that before beginning with the cutting activity, the coolant is turned on.

- In cases, where dry dressing is performed, do not apply the tool incessantly for longer time, in order to avoid high temperature. Allow the tool to cool naturally instead of doing it with the aid of a coolant. A sudden change in temperature can possibly cause fracture to the diamond, essentially not at the time of shock but in the future use of the tool.

- A diamond dresser should never be worn down to the shank as this might result in dropping out of the diamond. Usually, a Win Win diamond dresser mounted in a dressing tool has more hidden points which, if desired, may be used by Re-Setting.

- A crucial point to be remembered is not to allow a large flat to develop on the cutting point as this may deteriorate the economic life of the diamond.